SMT Splice Tapes & Tools

Automatic SMT Splicing Machine

Applicable for all types of 8mm carrier tapes.

Features

Application

For jointing carrier tapes in the SMT process

Specification

- Automatic splicing

- Applicable for all types of 8mm carrier tapes.

- Improve the splicing speed and FPY (≥99.3%)

- Low noise: unique non-vacuum splicing design to avoid excessive noise.

- Hot-melt splicing tape are applied for improving the splicing strength, the carrier tape will not loose or break when moving in the feeder.

Application

For jointing carrier tapes in the SMT process

Specification

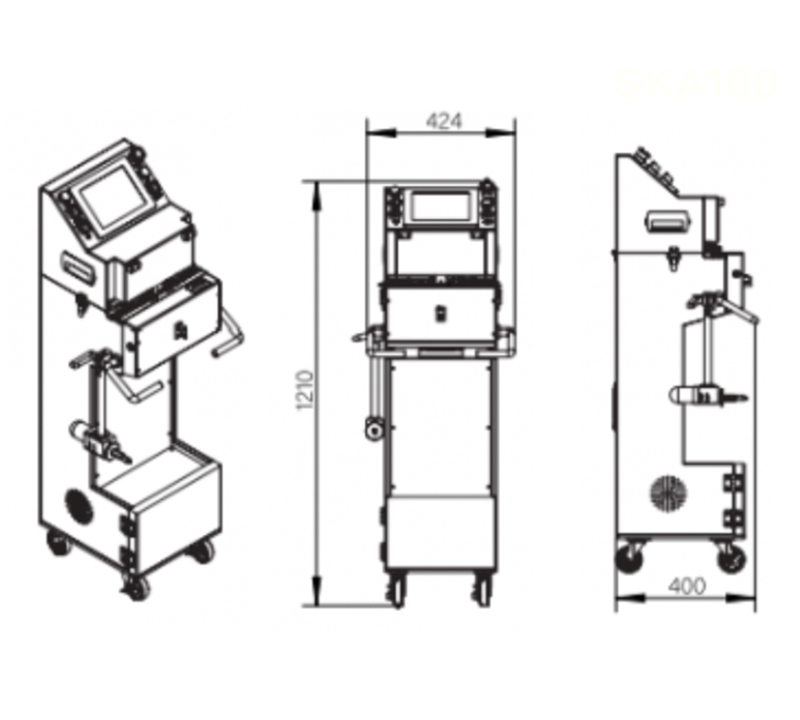

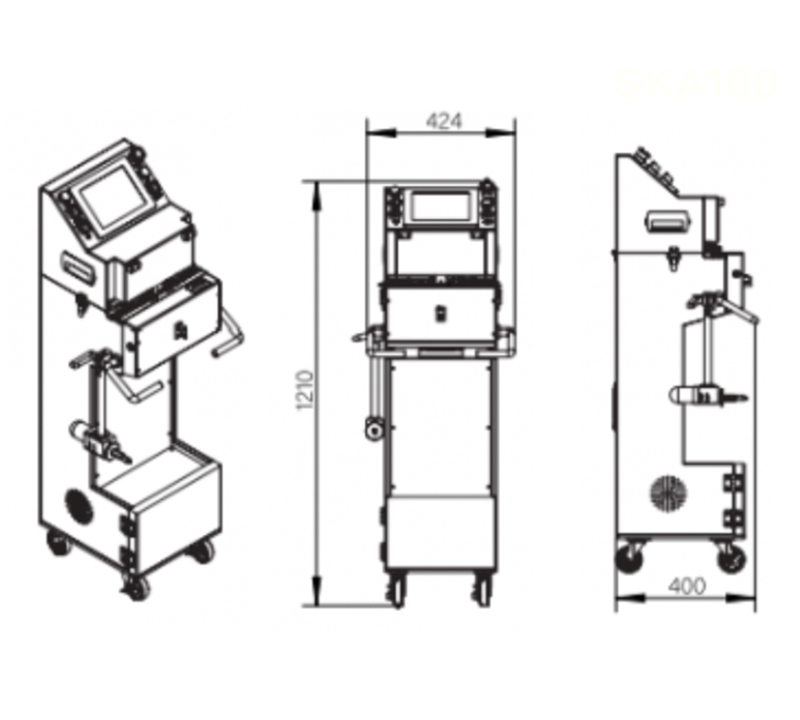

| Appearance | Dimension/mm: L400*W424*H1,210 Weight/kg: 60 |

| Conveyor | Conveyor Height/mm: 920±10 Width/mm: 8 |

| Carrier Tape | Material: Paper /Plastics Width/mm: 8 Pitch/mm: 2, 4 Minimum Splicing Length/mm: 120 |

| Splicing Tape | Length of Splicing Tape/mm: 32 |

| Accuracy | Carrier Tape Feeding accuracy: ±0.10mm Misalignment accuracy: ±0.15mm |

| Power Supply System | Battery Capacity/Ah: 22 Battery Voltage/V: 48 Charging Voltage/V: 110-220 Charge Time/ Hour: 8 Full Charge Working Time/ Hour:12-16 |

| Splicing Efficiency | Splicing Time (C/T)/Sec: 12-15 (Loading time isn’t included) Winding Speed/RPM: 300 Empty Component Spliced/pcs: 0-2 |

| FPY | Empty Component Spliced/pcs: 0-2 |

| Accuracy | Misalignment Accuracy/mm: ±0.15 |

| Rewinding | Control Mode: Automatic Reset Button Winding Device: One Set (Left Side) Carrier Tape Reel/ Inch: 7/ 13/ 15 |

| Control System | VCU PLC + Smart Control |

| Empty Component Detection | Visual Inspection (Component 01005 and above ) |

| Optional Accessories | Automatic Pre-Cutting Device Barcode Scanner Automatic Brass Press Receiving Device |