Mold Parts

Linear needle guide unit

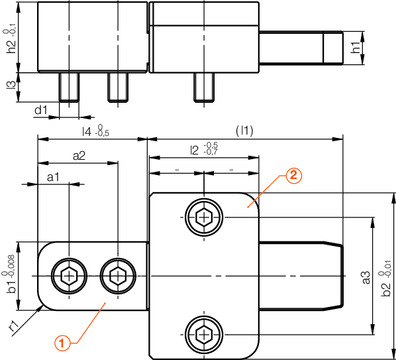

- Hasco Z073/b1xl2xl1

- max. 200°C

- 60 HRC

- 1.2379 / brass

Linear needle guide unit

| n2 | Pos2 | n1 | Pos1 | r1 | a3 | a2 | a1 | h2 | h1 | b2 | l3 | d1 | b1 | l2 | l1 | Product |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Z0732/12x27 | 1 | Z0731/12x25 | 4 | 29 | 20 | 7 | 22 | 9 | 45 | 9,8 | M6 | 12 | 27 | 25 |

Z073/12x27x25

|

| 1 | Z0732/12x27 | 1 | Z0731/12x50 | 4 | 29 | 20 | 7 | 22 | 9 | 45 | 9,8 | M6 | 12 | 27 | 50 |

Z073/12x27x50

|

| 1 | Z0732/17x36 | 1 | Z0731/17x32 | 6 | 35 | 26 | 10 | 25 | 9 | 50 | 11,8 | M6 | 17 | 36 | 32 |

Z073/17x36x32

|

| 1 | Z0732/17x36 | 1 | Z0731/17x63 | 6 | 35 | 26 | 10 | 25 | 9 | 50 | 11,8 | M6 | 17 | 36 | 63 |

Z073/17x36x63

|

| 1 | Z0732/25x46 | 1 | Z0731/25x40 | 8 | 45 | 33 | 13 | 32 | 13 | 63 | 12 | M8 | 25 | 46 | 40 |

Z073/25x46x40

|

| 1 | Z0732/25x46 | 1 | Z0731/25x80 | 8 | 45 | 33 | 13 | 32 | 13 | 63 | 12 | M8 | 25 | 46 | 80 |

Z073/25x46x80

|

| 1 | Z0732/35x56 | 1 | Z0731/35x50 | 10 | 60 | 41 | 16 | 36 | 17 | 85 | 15 | M10 | 35 | 56 | 50 |

Z073/35x56x50

|

| 1 | Z0732/35x56 | 1 | Z0731/35x100 | 10 | 60 | 41 | 16 | 36 | 17 | 85 | 15 | M10 | 35 | 56 | 100 |

Z073/35x56x100

|

| 1 | Z0732/45x66 | 1 | Z0731/45x56 | 10 | 74 | 48 | 18 | 40 | 17 | 100 | 18 | M12 | 45 | 66 | 56 |

Z073/45x66x56

|

| 1 | Z0732/45x66 | 1 | Z0731/45x112 | 10 | 74 | 48 | 18 | 40 | 17 | 100 | 18 | M12 | 45 | 66 | 112 |

Z073/45x66x112

|

The HASCO linear needle guide unit Z073/... sets completely new standards in precision and rollingfriction. Thanks to the very tight fitting tolerance of the circulating needles, it reliably guides and centres injection moulding units and die-casting moulds. As well as sub-assembly Z073/..., the square centering guide Z0731/... and the linear needle guide unit Z0732/... are also available separately.

- High-precision, flat guiding of injection moulding tools

- System operates virtually free of play through very tight fitting tolerance

- Circulating needles enable unlimited stroke

- Large contact surface of the needles

- Specifically for stripper plates

- Low wear through rolling friction

- Max. service temperature 200°C

- Recommended high-performance lubricating spray Z261/...

- Fixing material is included