Dispensing

Needle control valve Musashi Mini Val NCV-17

High-precision standard valve

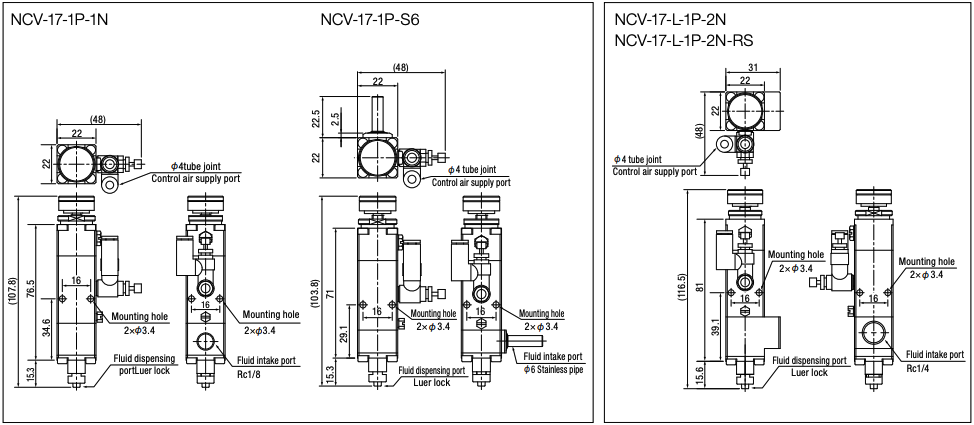

- NCV-17-1P-1N

- NCV-17-1P-S6

- NCV-17-L-1P-2N

- NCV-17-L-1P-2N-RS

- Also capable of micro-deposit dispensing fluid materials containing UV and filler.

- Reduces air bubbles mixing.

- Diaphragm structure prevents fluid material from entering sliding parts.

- The square-shaped, compact and lightweight valves are ideal for use with automated equipment.

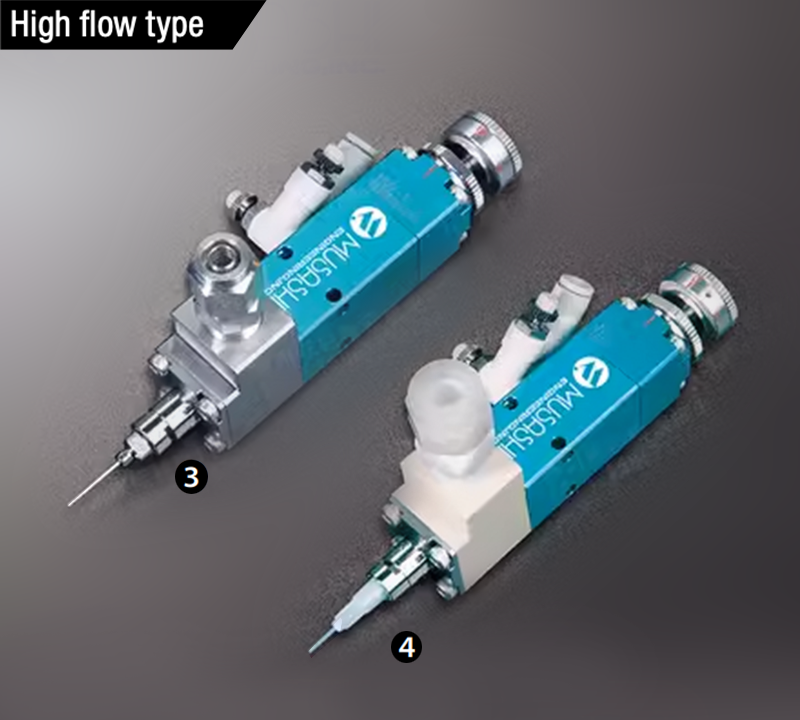

- High flow type are also available with approx. 3x fluid flow rate.

| 1. Type17 1 port | 2. Type17 1 port OD 6 mm SUS pipe attached | 3. Type17 1 port high flow | 4. Type17 1 port high flow rate resin specification | |

|---|---|---|---|---|

| Model | NCV-17-1P-1N | NCV-17-1P-S6 | NCV-17-1P-2N | NCV-17-1P-2N-RS |

| Driving system | Pneumatic driven system | |||

| Minimum dispensing amount | 3 μL— | 9 μL— | ||

| Compatible viscosity | Up to 50 Pa·s | |||

| Control air supply pressure range | 0.35 to 0.5 MPa | |||

| Fluid material supply pressure range | Max. 0.5 Mpa | |||

| Maximum number of cycles | 680 times/min. | |||

| Fluid intake port | Rc1/8 (fluid feed joint ordered separately) |

OD 6 mm Stainless pipe (fluid feed joint ordered separately) |

Rc1/4 (fluid feed joint ordered separately) |

|

| Fluid dispensing port | Luer lock | |||

| Control air | One-touch joint for φ4 outer diameter tube (with speed controller) | |||

| Operating temperature range | 5 to 60°C | |||

| Wetted part material | Stainless steel, Fluorine resin, Polyacetal | Stainless steel, Fluorine resin | PEEK, fluorine resin | |

| Weight | 193 g | 216 g | 222 g | 149 g |