Dispensing

Nordson EFD 794 794-TC Auger Valves

Part No.:

7029742 794-FB Valve

7363512 794-TC Valve

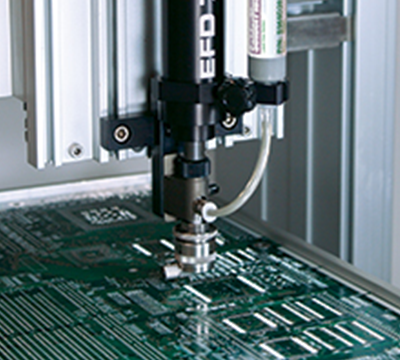

The 794 Series auger valve makes precise, repeatable deposits without damage to the metal alloy particles in fluids such as solder paste and silver epoxies. For highly abrasive fluids such as thermal interface materials (TIM), use the 794-TC Auger Series with tungsten carbide wetted parts.

7029742 794-FB Valve

7363512 794-TC Valve

The 794 Series auger valve makes precise, repeatable deposits without damage to the metal alloy particles in fluids such as solder paste and silver epoxies. For highly abrasive fluids such as thermal interface materials (TIM), use the 794-TC Auger Series with tungsten carbide wetted parts.

Using screw feed principles combined with precision time and pressure controls, the 794 Series system ensures consistent deposits while eliminating damage to particle-filled fluids. It is available with two motor types – brush or brushless. The brushless motor is ideal for high speeds and high cycle rate microdot dispensing. The 794 Series also includes a sliding head/footed tip feature that maintains a consistent dispense gap when applying fluids to surfaces with irregular heights.

The 794-TC Series auger valve system is designed to make precise, repeatable deposits of thermal interface materials and other highly abrasive pastes. It’s designed with a brush motor ideal for lines and stripes with dispense cycle rates up to 60 to 90 shots per minute. The valve’s tungsten carbide construction provides long valve life.

The 794 / 794-TC Series auger dispense valves can be supplied with solder paste or thermal compounds from prefilled syringe barrels or cartridges.

Features

The complete system includes the 794 or 794-TC Series auger valve, ValveMate™ 7194 controller, fluid reservoir, and dispense tip. Integrate with an EFD automated dispensing system for even faster throughput.

Learn more about our wide range of reliable, high-quality solder pastes, thermal compounds, print pastes, and dispense flux, including specialized solder formulations. For non-contact applications, the Liquidyn® P-Jet SolderPlus® jetting system delivers highly repeatable, fast solder paste dispensing results with pre-qualified formulations that streamline implementation.

Part Numbers

The 794-TC Series auger valve system is designed to make precise, repeatable deposits of thermal interface materials and other highly abrasive pastes. It’s designed with a brush motor ideal for lines and stripes with dispense cycle rates up to 60 to 90 shots per minute. The valve’s tungsten carbide construction provides long valve life.

The 794 / 794-TC Series auger dispense valves can be supplied with solder paste or thermal compounds from prefilled syringe barrels or cartridges.

Features

- Adjustable auger speed

- Adjustable flow rate

- Fixed head version for lines and stripes

- Solder paste

- Particle-filled materials

- Thermal interface materials

- Silver epoxies

The complete system includes the 794 or 794-TC Series auger valve, ValveMate™ 7194 controller, fluid reservoir, and dispense tip. Integrate with an EFD automated dispensing system for even faster throughput.

Learn more about our wide range of reliable, high-quality solder pastes, thermal compounds, print pastes, and dispense flux, including specialized solder formulations. For non-contact applications, the Liquidyn® P-Jet SolderPlus® jetting system delivers highly repeatable, fast solder paste dispensing results with pre-qualified formulations that streamline implementation.

Part Numbers

| 794/794-TC Auger Valves | ||

| Part # | Description | Specification |

| 7029742 | 794-FB Valve | Auger valve, 8 pitch, brushless motor, fixed head |

| 7029745 | 794-FR Valve | Auger valve, 8 pitch, brush motor, fixed head |

| 7029746 | 794-FR-16 Valve | Auger valve, 16 pitch, brush motor, fixed head |

| 7363512 | 794-TC Valve | Auger valve, high flow (double pitch), 0.10 mm (0.004") gap |

| 7364566 | 794-TC Valve | Auger valve, high flow (double pitch), 0.15 mm (0.006") gap |