Machinery Parts

Precision Grinding Spindle

Types and Features

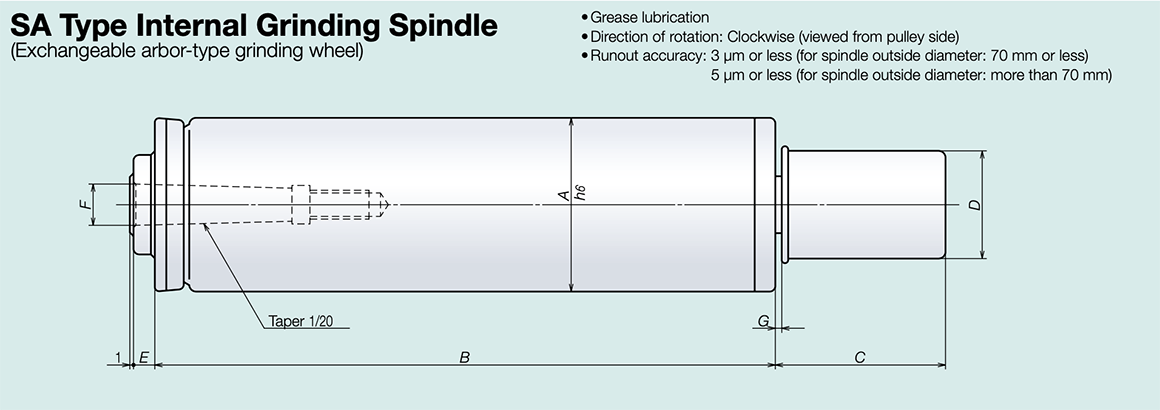

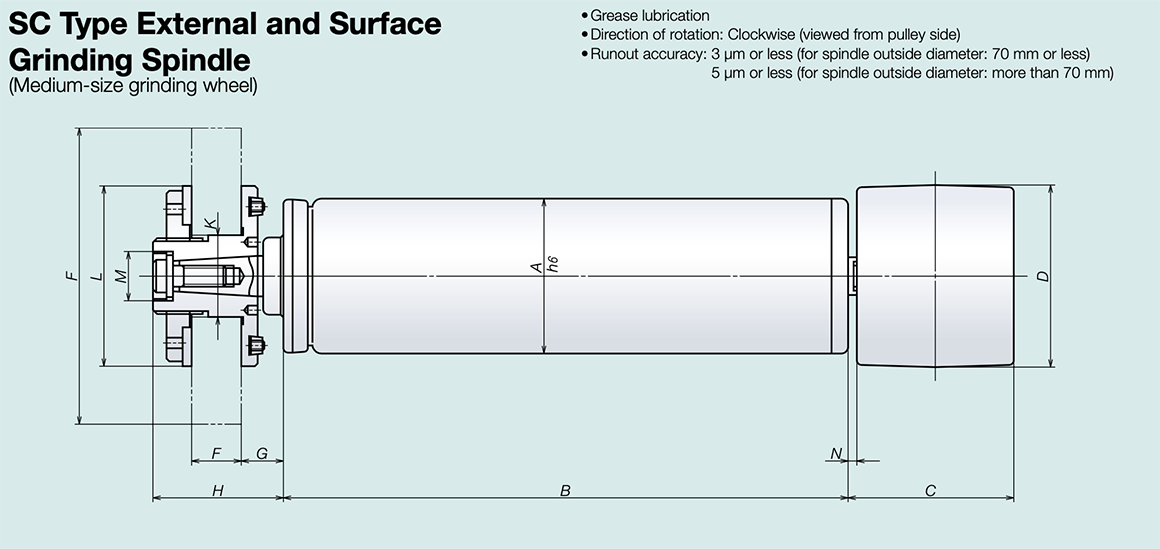

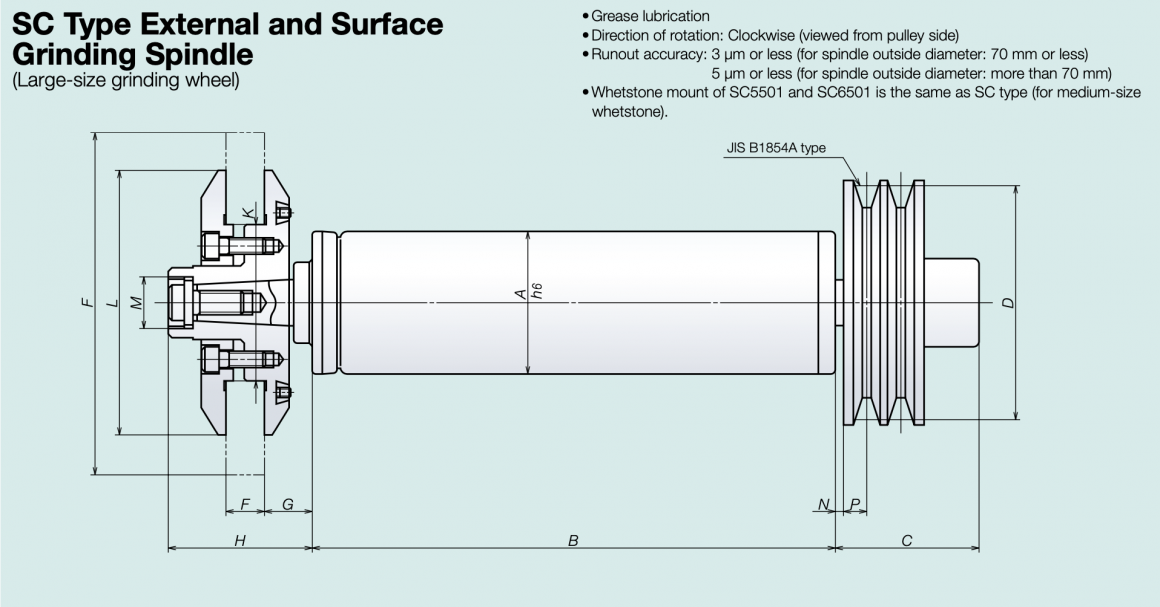

SA Type Quill type spindle for various exchangeable wheel arbors. Can be used for a wide range of applications.SC Type Two types available - flat-belt driven spindles for medium-size grinding wheels, and V-belt driven spindles for large-size grinding wheels.

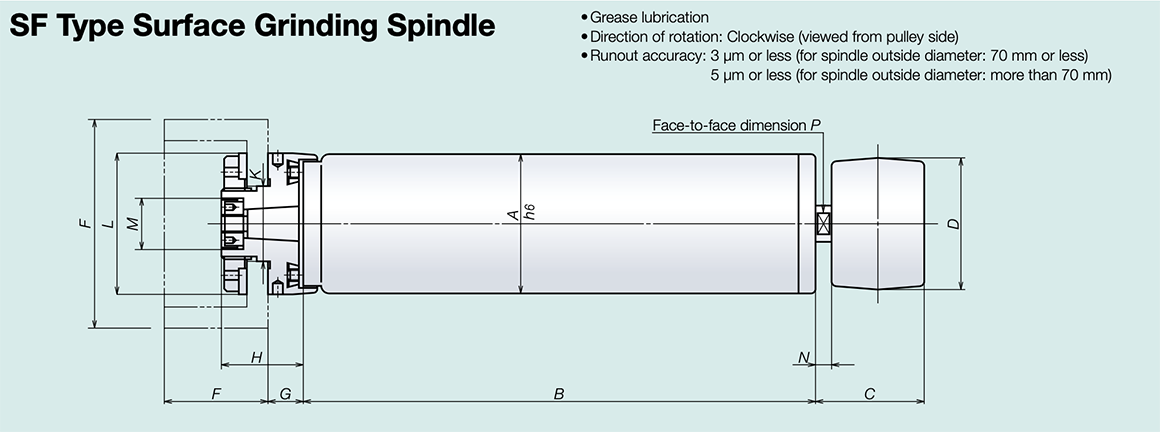

SF Type Flat-belt driven spindle for cup-type grinding wheels. Incorporates precision bearings with high load capacity.

- Runout accuracy: Less than 3 um for all types with outside cylinder diameter of less than 70 mm. Less than 5 um for all types with outside cylinder diameter of 70 mm or greater. (SA Type: Base of test bar. SC and SF Types: End of spindle shaft.)

- Spindles for counterclockwise rotation can be manufactured for special orders.

Selection Criteria

| Type of grinding | Type | Suitable applications |

| Internal grinding | SA | Exchangeable grinding wheel arbor type. Use when grinding various types of holes. |

| External grinding | SC | Two types - one for use with mediumn-size grinding wheels, one for use with large-size grinding wheels. |

| Surface grinding | SC | Use when grinding surfaces with the outer circumference of the grinding wheel. |

| SF | Use when grinding surfaces with the end face of a cup-type or dish-type grinding wheel. |

Note: Please select the size suited to the mounting conditions.

Please select the spindle suited to the grinding conditions.

Unit: mm

| Spindle reference No. | Max. rot. speed(min-1) | A | B | C | D | E | F | G |

| SA600 | 30 000 | 60 | 220 | 48 | 28 | 8 | 11.113 | 3 |

| SA700 | 20 000 | 70 | 250 | 69 | 42 | 9 | 17.463 | 3 |

| SA800 | 16 000 | 80 | 280 | 73 | 56 | 9 | 20.638 | 3 |

| SA900 | 13 500 | 90 | 320 | 84 | 63 | 9 | 23.813 | 4 |

Unit: mm

| Spindle reference No. | Max. rot. speed(min-1) | A | B | C | D | E | F | G | H | K | L | M | N |

| SC5500 | 6 400 | 50 | 180 | 47 | 56 | 65 - 90 | 9.5 - 13 | 15.5 | 41 | 22.23 | 50 | M14 x 1.5 | 2 |

| SC6500 | 5 000 | 60 | 220 | 63 | 70 | 75 - 115 | 13 - 19 | 17 | 51 | 31.75 | 70 | M20 x 1.5 | 3 |

| SC7500 | 3 800 | 70 | 250 | 73 | 90 | 100 - 150 | 16 - 25 | 24 | 70 | 38.1 | 90 | M26 x 1.5 | 3 |

| SC8500 | 3 200 | 80 | 280 | 83 | 110 | 125 - 180 | 19 - 32 | 24 | 80 | 63.5 | 115 | M30 x 1.5 | 3 |

Unit: mm

| Spindle reference No. | Max. rot. speed(min-1) | A | B | C | D | E | F | G | H | K | L | M | N | P |

| SC5501 | 5 700 | 50 | 180 | 47 | 60 | 65 - 100 | 9.5 - 13 | 15.5 | 41 | 22.23 | 50 | M14 x 1.5 | 2 | 10 |

| SC6501 | 4 600 | 60 | 220 | 48 | 80 | 75 - 125 | 13 - 19 | 17 | 51 | 31.75 | 70 | M20 x 1.5 | 3 | 10 |

| SC7501 | 3 200 | 70 | 250 | 69 | 110 | 150 - 180 | 16 - 19 | 24 | 70 | 76.2 | 130 | M26 x 1.5 | 3 | 10.5 |

| SC8501 | 2 800 | 80 | 280 | 73 | 130 | 150 - 205 | 19 - 25 | 24 | 80 | 76.2 | 130 | M30 x 1.5 | 3 | 10.5 |

Unit: mm

| Spindle reference No. | Max. rot. speed(min-1) | A | B | C | D | E max. |

F | G | H | K | L | M | N | P |

| SF5500 | 7 600 | 50 | 180 | 47 | 48 | 75 | 38 | 13 | 32 | 25.4 | 50 | - | 7 | 12 |

| SF6500 | 6 400 | 60 | 220 | 47 | 56 | 90 | 45 | 15 | 35 | 31.75 | 60 | M22 x 1.5 | 7 | 12 |

| SF7500 | 5 700 | 70 | 250 | 64 | 63 | 100 | 50 | 15 | 39 | 38.1 | 70 | - | 9 | 19 |

| SF8500 | 5 000 | 80 | 280 | 64 | 70 | 115 | 50 | 15 | 39 | 38.1 | 80 | - | 9 | 23 |

Unit: mm

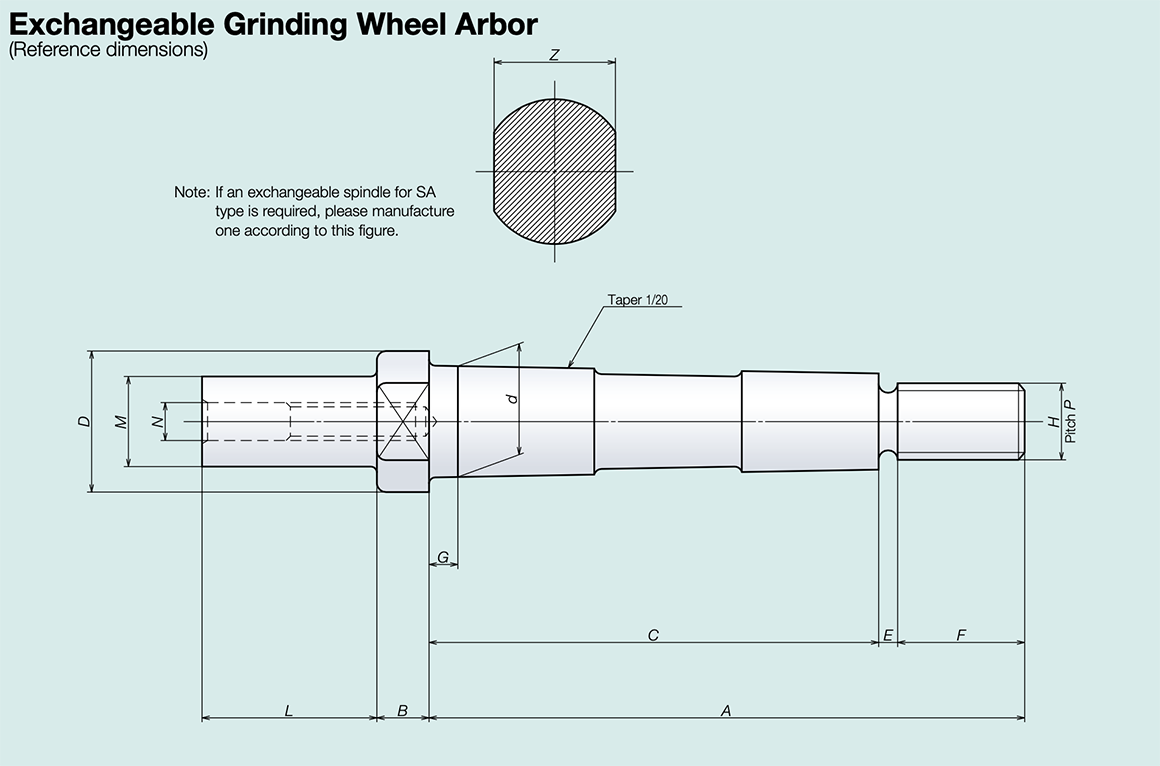

| Spindle reference No. | A | B | C | D | d | E | F | G | H | P | Z | M Recommended dimensions |

| SA600 | 66 | 6 | 50 | 14 | 11.113 | 3 | 13 | 3 | 8 | 1.25 | 12 | 5, 6, 8, 10, 12 |

| SA700 | 94 | 8 | 71 | 22 | 17.463 | 3 | 20 | 4 | 12 | 1.75 | 19 | 5, 6, 8, 10, 12, 14, 16, 18 |

| SA800 | 105 | 9 | 78 | 25 | 20.638 | 4 | 23 | 4 | 14 | 2 | 21 | 6, 8, 10, 12, 14, 16, 18, 21 |

| SA900 | 118.5 | 11.5 | 86.5 | 30 | 23.813 | 6 | 26 | 4.5 | 16 | 2 | 26 | 10, 12, 14, 16, 18, 21, 24 |

Note: The maximum length L, with respect to the exchangeable grinding wheel arbor neck with outer diameter M, can be determined using the table on the right.

Unit: mm

| Neck outside diameter M |

5 | 6 | 8 | 19 | 12 | 14 | 16 | 18 | 21 | 24 |

| Screw thread diameter N |

3 | 3 | 3 | 4 | 6 | 6 | 6 | 8 | 8 | 8 |

| Maximum length L |

30 | 35 | 45 | 50 | 60 | 68 | 72 | 81 | 97 | 108 |

Speed of SC and SF Type

When motor speed is 3 000 min-1, motor pulley diameter is Ø 120 and the maximum dimension of the grinding wheel (E) is used, theginding speed is approximately 1 800 m/min. If operating conditions deviate from these conditions, please determine the appropriate

pulley diameter to obtain a grinding speed of 1 800 m/min with the grinding wheel diameter used.