Soldering

Pulsed Heat HBR HSC ACF Bonding System

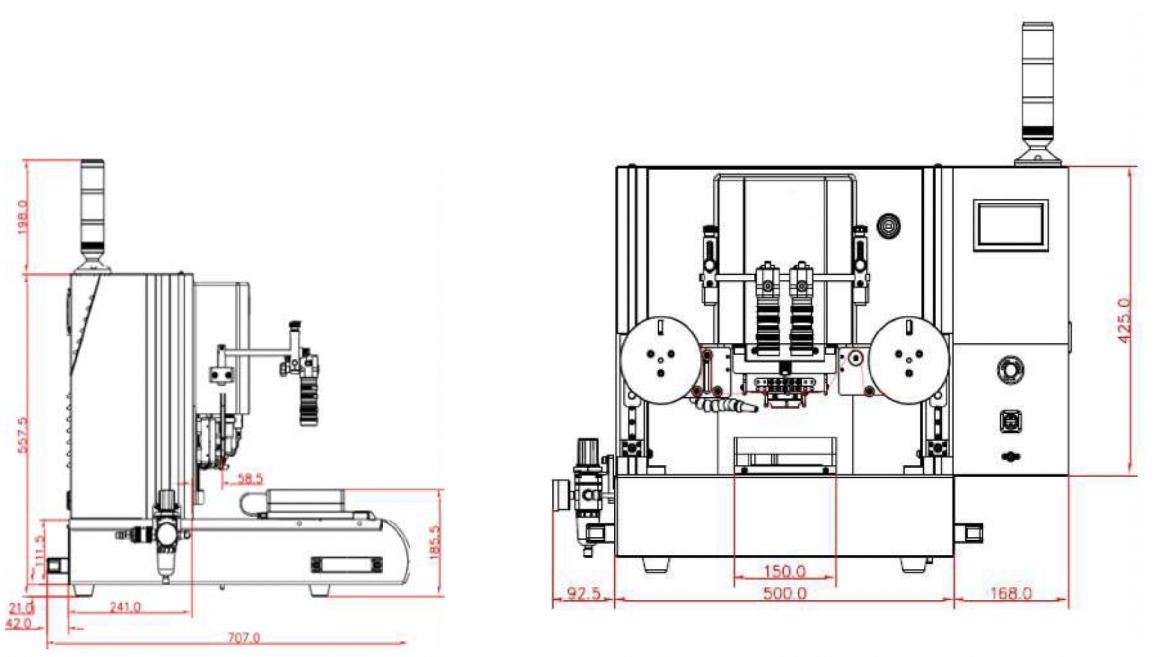

MODEL NO.: HB212/202

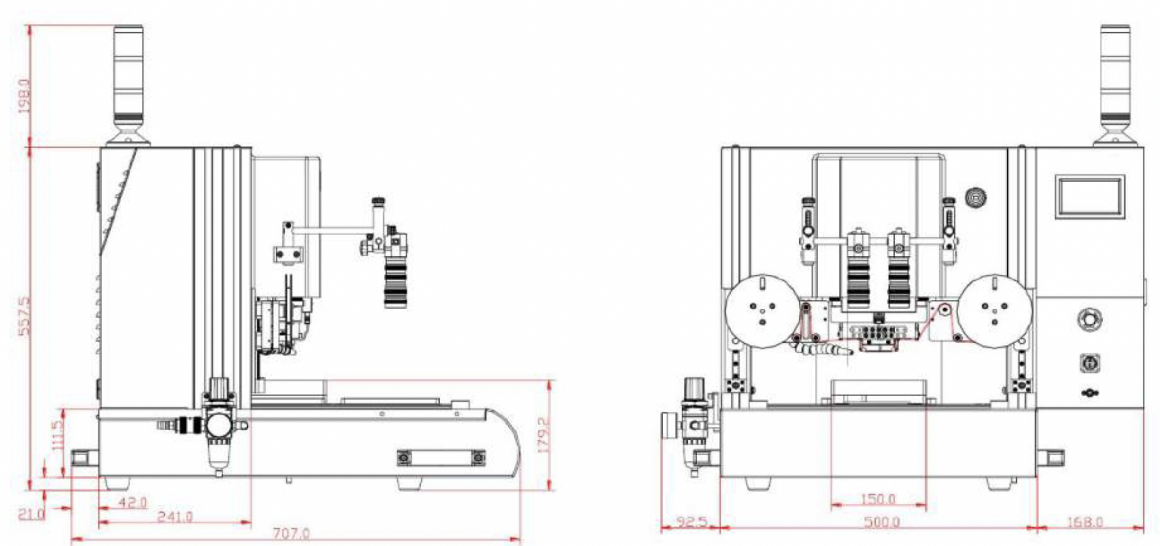

MODEL NO.: HB213/203

MODEL NO.: HB213/203

Pulsed Heat HBR HSC ACF Bonding System HB212 202 213 203

Features

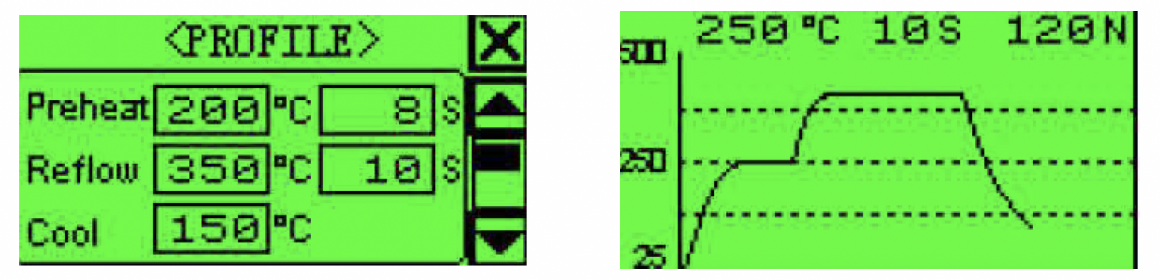

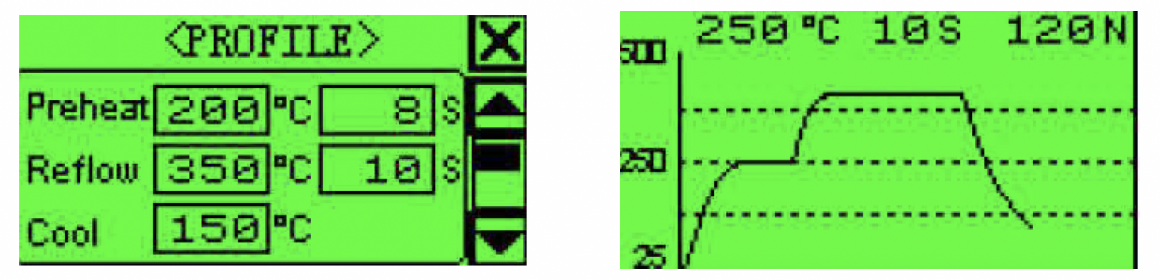

1) Realtime temperature and force profile display on the LCD touch screen.

2) Titanium alloy thermode ensure uniform temperature distribution,

fast heating and longest service life.

3) Password protection for process and system parameters.

4) Level mechanism for components co-planarity adjustment.

5) English / Simplified Chinese user interface display.

Options

1) Tape Feeding System (TFS1) for holding silicon or Polyimid (Kapton) tape.

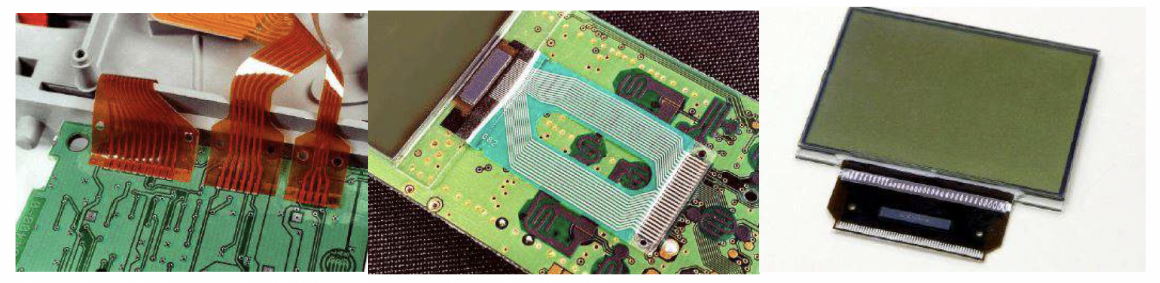

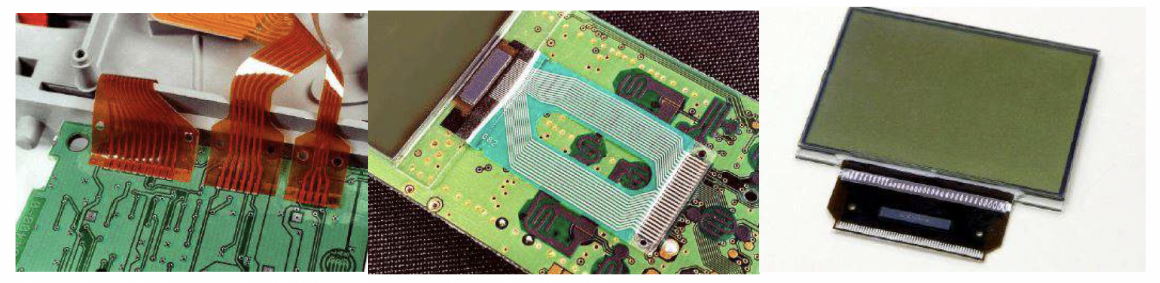

2) Colour (CC19) alignment module for TAB/flex to PCB/LCD.

3) Thermal Profiling Unit (TPU1); additional thermocouples

for temperature profile monitoring.

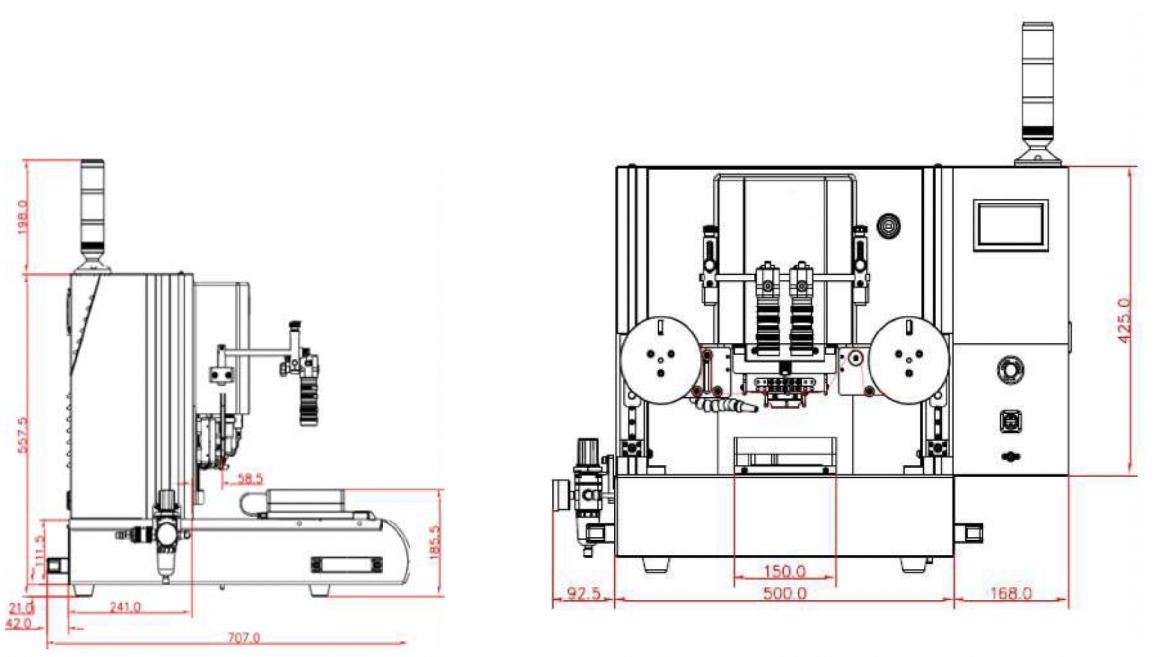

HB212 / 202 Technical Specifications

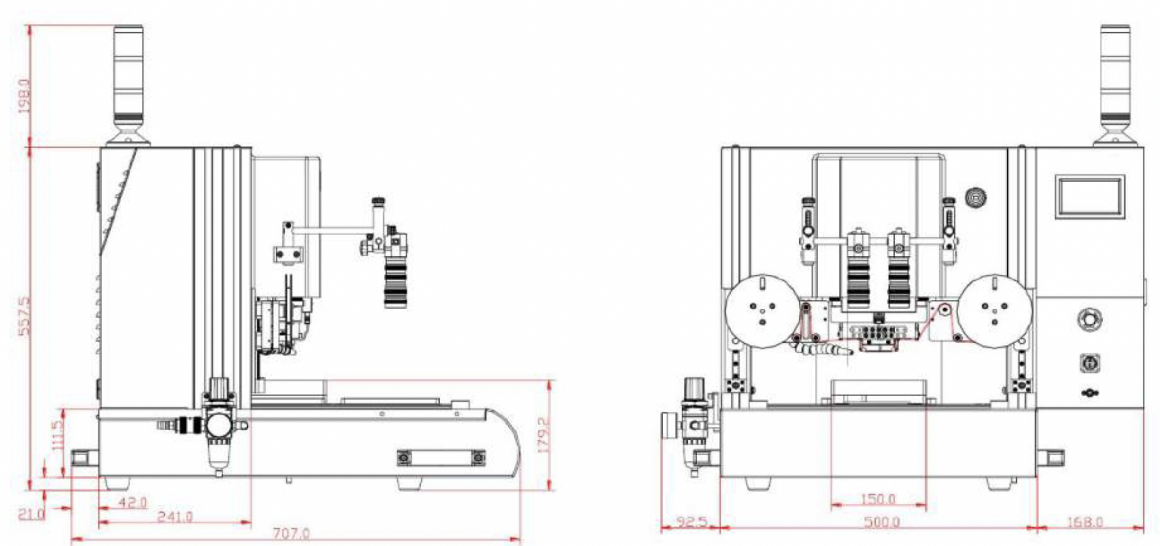

HB213 / 203 Technical Specifications

Features

1) Realtime temperature and force profile display on the LCD touch screen.

2) Titanium alloy thermode ensure uniform temperature distribution,

fast heating and longest service life.

3) Password protection for process and system parameters.

4) Level mechanism for components co-planarity adjustment.

5) English / Simplified Chinese user interface display.

Options

1) Tape Feeding System (TFS1) for holding silicon or Polyimid (Kapton) tape.

2) Colour (CC19) alignment module for TAB/flex to PCB/LCD.

3) Thermal Profiling Unit (TPU1); additional thermocouples

for temperature profile monitoring.

HB212 / 202 Technical Specifications

| SYSTEM SPECIFICATIONS | |

| Dimensions (Without signal tower) | 750 mm x 760 mm x 558 mm |

| Weight (Not including the CCD and LCD monitor) | 88 Kg |

| Power consumption | 220V / 60Hz or 110V / 50Hz, 2KVA (Factory preset) |

| Air supply | 4 to 6 Kg/cm2 |

| Maximum fixture height | 48 mm |

| Fixture assembly baseplate | 150 mm x 150 mm ( 1 sets) |

| Starting operation method | Two hand control |

| Turntable actuation | Pneumatic (PBS212); Manual (PBS202) |

| Vacuum for components holding 1 sets | 1 sets; built-in |

| Password | 6 digits (2-level) |

| THERMODE SPECIFICATIONS | |

| Force range | 30 N to 500 N |

| Force accuracy | ±2 N |

| Actuation type | Pneumatic |

| Thermode stroke | 50 mm maximum |

| Thermode length | 100 mm maximum |

| PULSED HEAT CONTROL SPECIFICATIONS | |

| Heating method | Pulsed heating, high speed PID control |

| Temperature range preheat 50 to | 50 to 500℃ (1 degree increment) |

| Temperature range heat | 50 to 500 ℃(1 degree increment) |

| Time period preheat | 1 to 60 seconds (1 second increment) |

| Time period heat | 1 to 60 seconds (1 second increment) |

| Temperature accuracy | ±2℃ |

| Programmable heat profile | 3 programs, non-volatile |

| Thermocouple | K type |

| Communication port | RS-232C |

HB213 / 203 Technical Specifications

| SYSTEM SPECIFICATIONS | |

| Dimensions (Without signal tower) | 630 mm x 520 mm x 500 mm |

| Weight (Not including the CCD and LCD monitor) | 66 Kg |

| Power consumption | 220V / 60Hz or 110V / 50Hz, 2KVA (Factory preset) |

| Air supply | 4 to 6 Kg/cm2 |

| Maximum fixture height | 48 mm |

| Fixture assembly baseplate | 150 mm x 150 mm (2 sets) |

| Starting operation method | Two hand control |

| Turntable actuation | Pneumatic (PBS213); Manual (PBS203) |

| Vacuum for components holding 1 sets | 2 sets; built-in |

| Password | 6 digits (2-level) |

| THERMODE SPECIFICATIONS | |

| Force range | 20 N to 500 N |

| Force accuracy | ±2 N |

| Actuation type | Pneumatic |

| Thermode stroke | 50 mm maximum |

| Thermode length | 100 mm maximum |

| PULSED HEAT CONTROL SPECIFICATIONS | |

| Heating method | Pulsed heating, high speed PID control |

| Temperature range preheat 50 to | 50 to 500℃ (1 degree increment) |

| Temperature range heat | 50 to 500 ℃(1 degree increment) |

| Time period preheat | 1 to 60 seconds (1 second increment) |

| Time period heat | 1 to 60 seconds (1 second increment) |

| Temperature accuracy | ±2℃ |

| Programmable heat profile | 3 programs, non-volatile |

| Thermocouple | K type |

| Communication port | RS-232C |