Fastening

Brushless Servo Intelligent Torque Sensor Series

- Snap-action brushless servo electric screwdriver can realize free programming of tightening assembly process

- Within the range of performance parameters, the torque, speed, waiting time and rotation direction can be set and adjusted freely according to different tightening process requirements to achieve precise tightening.

Brushless Servo Intelligent Torque Sensor Series

Features

Technical parameter

Technical parameters

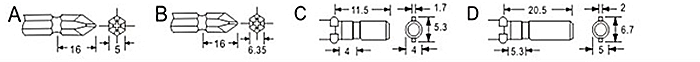

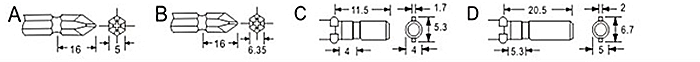

Optional specification of screwdriver bits

Features

- The quick-action brushless servo electric screwdriver can realize free programming of the tightening assembly process. Within the range of performance parameters, the torque, speed, waiting time and rotation direction can be freely set and adjusted according to different tightening process requirements to achieve precise tightening.

- Through the built-in torque sensor and angle sensor, the brushless servo electric screwdriver can be accurately controlled during each tightening process, and all important tightening process parameters can be recorded in real time.

- The quick-action brushless servo electric screwdriver is based on servo control technology, which can ensure that the torque accuracy of the millions of times tightening assembly is controlled within the standard deviation ±3%.

- The built-in current and angle measurement can realize the precise control and monitoring of the quick-action brushless servo electric screwdriver during each tightening process, realize the recording of all important tightening process parameters, and ensure the highest accuracy.

- Under normal working conditions, the quick-action brushless servo electric screwdriver can achieve Cmk≥1.67 (torque setting tolerance ±10%), which conforms to the principles of ISO 5393 and 6Sigma. The Cmk value of 1.67 means that there is only 0.6 error rate per million screws, that is, the pass rate is as high as 99.99994%.

- The quick-action brushless servo electric screwdriver adopts a brushless motor and cooperates with the SD-PF5015 or SD-PF5030 controller to ensure the flexibility and process reliability of the tightening process.

Technical parameter

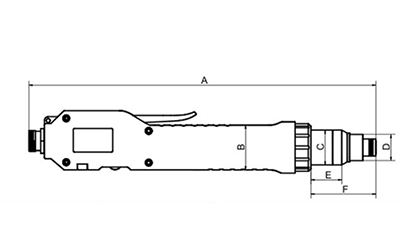

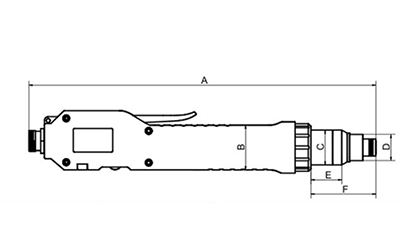

Physical dimension

| Model | A | B | C | D | E | F |

|---|---|---|---|---|---|---|

| SD-NCO8L-S SD-NC3OL-S SD-NC6OL-S |

227 | 28 | 31.5 | M16 | 6.5 | 28.8 |

| SD-NC 120L-S | 264 | 34 | 26.5 | M20 | 23.45 | 49.5 |

| SD-NC 200L-S SD-NC350L-S SD-NC500L-S |

300 | 40 | 32 | M20 | 37 | 72 |

| SD-NC1000AT-S SD-NC3500AT-S SD-NC 1500AT-S SD-NC5000AT-S SD-NC2300AT-S SD-NC7000AT-S |

350 | 45 | 40 | - | 45 | 80 |

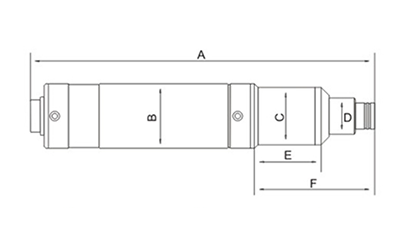

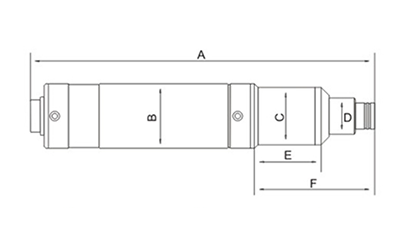

| Model | A | B | C | D | E | F |

|---|---|---|---|---|---|---|

| SD-NCO8AT-S SD-NC30AT-S SD-NC60AT-S |

160 | 25 | 23 | M13 | 25.3 | 48.1 |

| SD-NC120AT-S | 170.7 | 32 | 28.5 | M18 | 31.25 | 57.75 |

| SD-NC 200AT-S SD-NC350AT-S SD-NC500AT-S |

191.4 | 34 | 30 | M20 | 38.2 | 68.2 |

| SD-NC1000L-S SD-NC1500L-S SD-NC2300L-S SD-NC3500L-S SD-NC5000L-S SD-NC7000L-S |

250 | 44 | 40 | - | 49.2 | 59.2 |

Technical parameters

| Model | Measuring Range | No load speedi(r.p.m) | Input voltage | Weight(g) | Diameter of screw | ||

| Hand press | For automata | kgf.cm | N.cm | ||||

| SD-NC08L-S | SD-NC08AT-S | 0.1-0.8 | 0.01 -0.08 | 50-1200 | 48V | 260 | M1.0-M1.7 |

| SD-NC30L-S | SD-NC30AT-S | 0.1-3 | 0.01-0.3 | 50-2000 | M1.0-M2.0 | ||

| SD-NC60L-S | SD-NC60AT-S | 0.5-6 | 0.05-0.6 | 50-1200 | M1.2-M2.5 | ||

| SD-NC120L-S | SD-NC120AT-S | 1-12 | 0.1-1.2 | 50-1200 | 430 | M1.7-M4 | |

| SD-NC200L-S | SD-NC200AT-S | 1-20 | 0.1-2 | 50-1600 | 780 | M2.5-M6.0 | |

| SD-NC350L-S | SD-NC350AT-S | 5-35 | 0.5-3.5 | 50-800 | M4.0-M8.0 | ||

| SD-NC500L-S | SD-NC500AT-S | 5-50 | 0.5-5 | 50-500 | M4.5-M10 | ||

| SD-NC1000L-S | SD-NC1000AT-S | 20-100 | 2-10 | 50-1000 | 1150 | M6.0-M12 | |

| SD-NC1500L-S | SD-NC1500AT-S | 30-150 | 3-15 | 50-700 | M8.0-M14 | ||

| SD-NC2300L-S | SD-NC2300AT-S | 50-230 | 5-23 | 50-400 | 1250 | M10-M16 | |

| SD-NC3500L-S | SD-NC3500AT-S | 80-350 | 8-35 | 50-300 | M12-M18 | ||

| SD-NC5000L-S | SD-NC5000AT-S | 200-500 | 20-50 | 50-200 | M14-M20 | ||

| SD-NC7000L-S | SD-NC7000AT-S | 200-500 | 20-50 | 150 | M16-M22 | ||