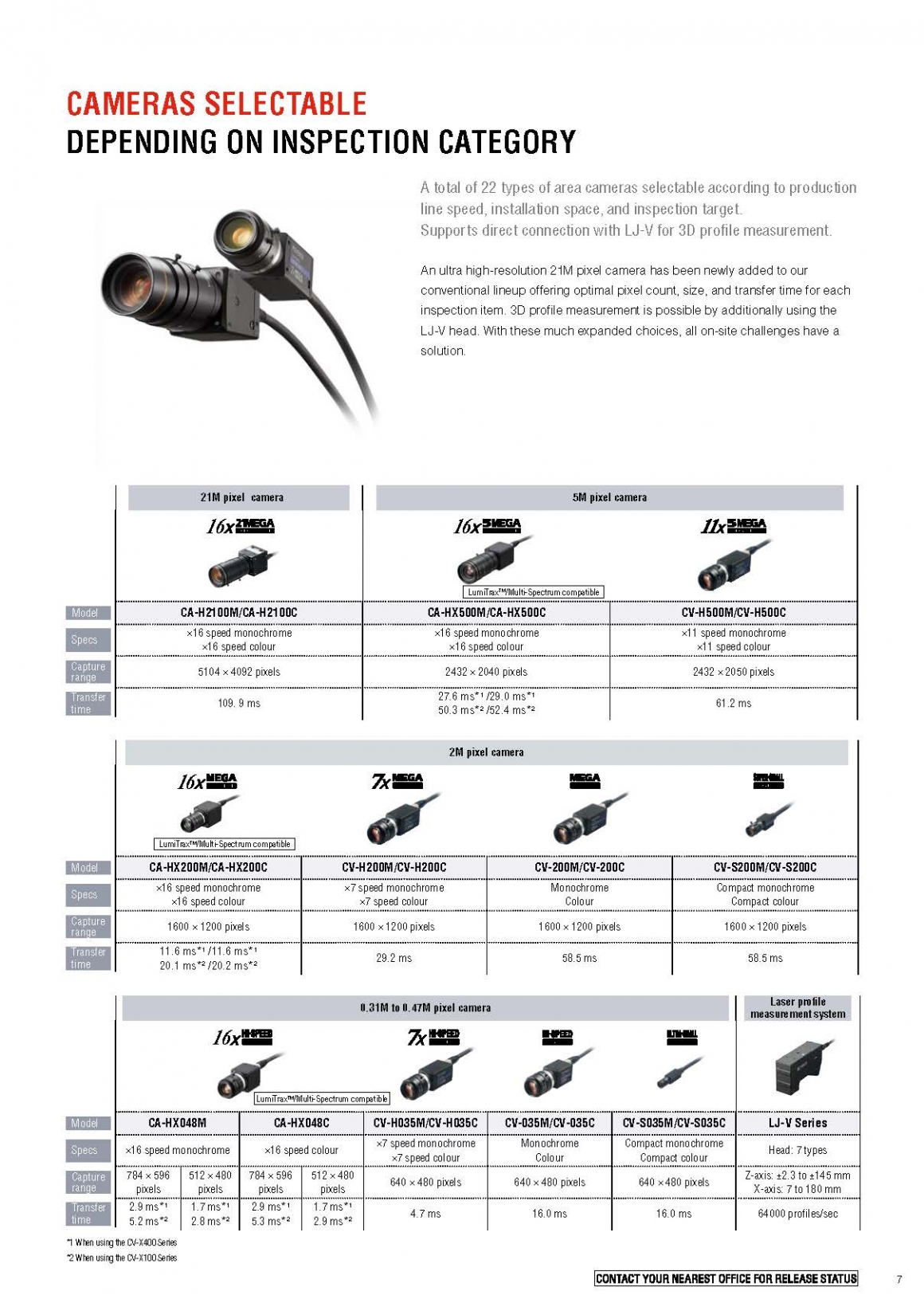

Machine

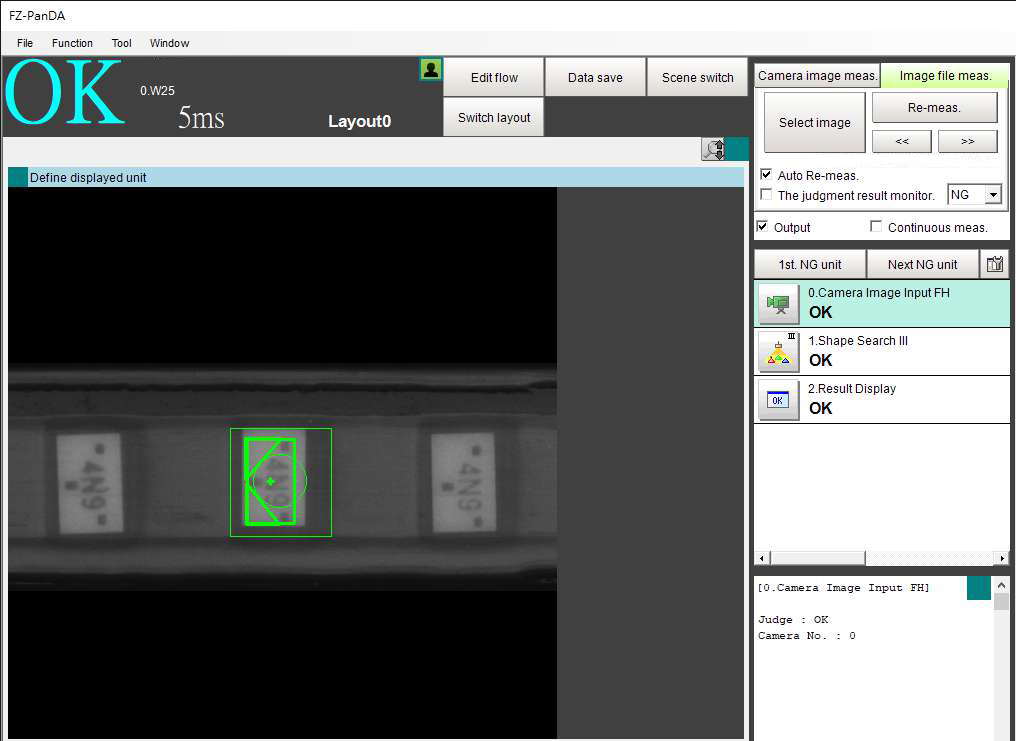

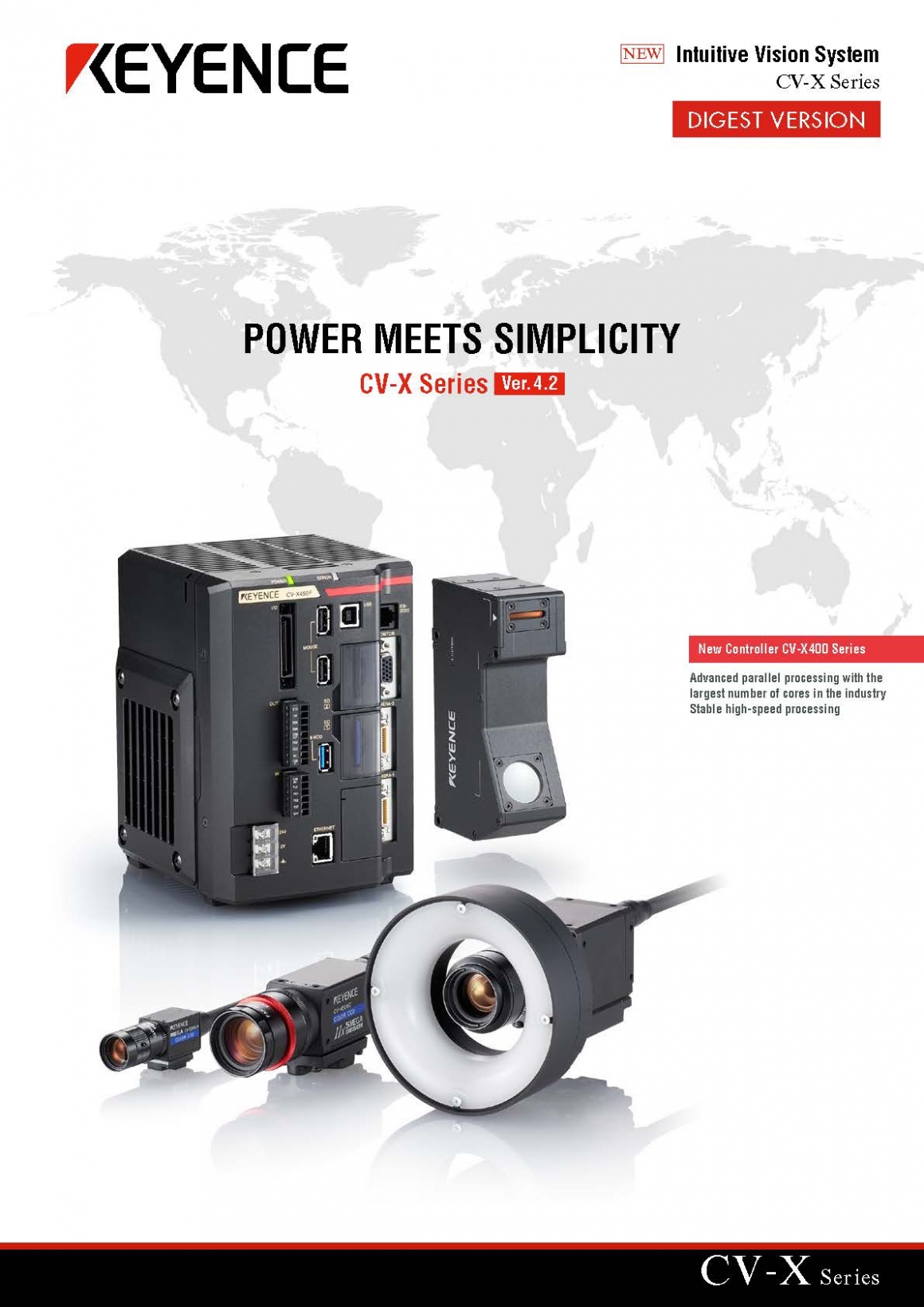

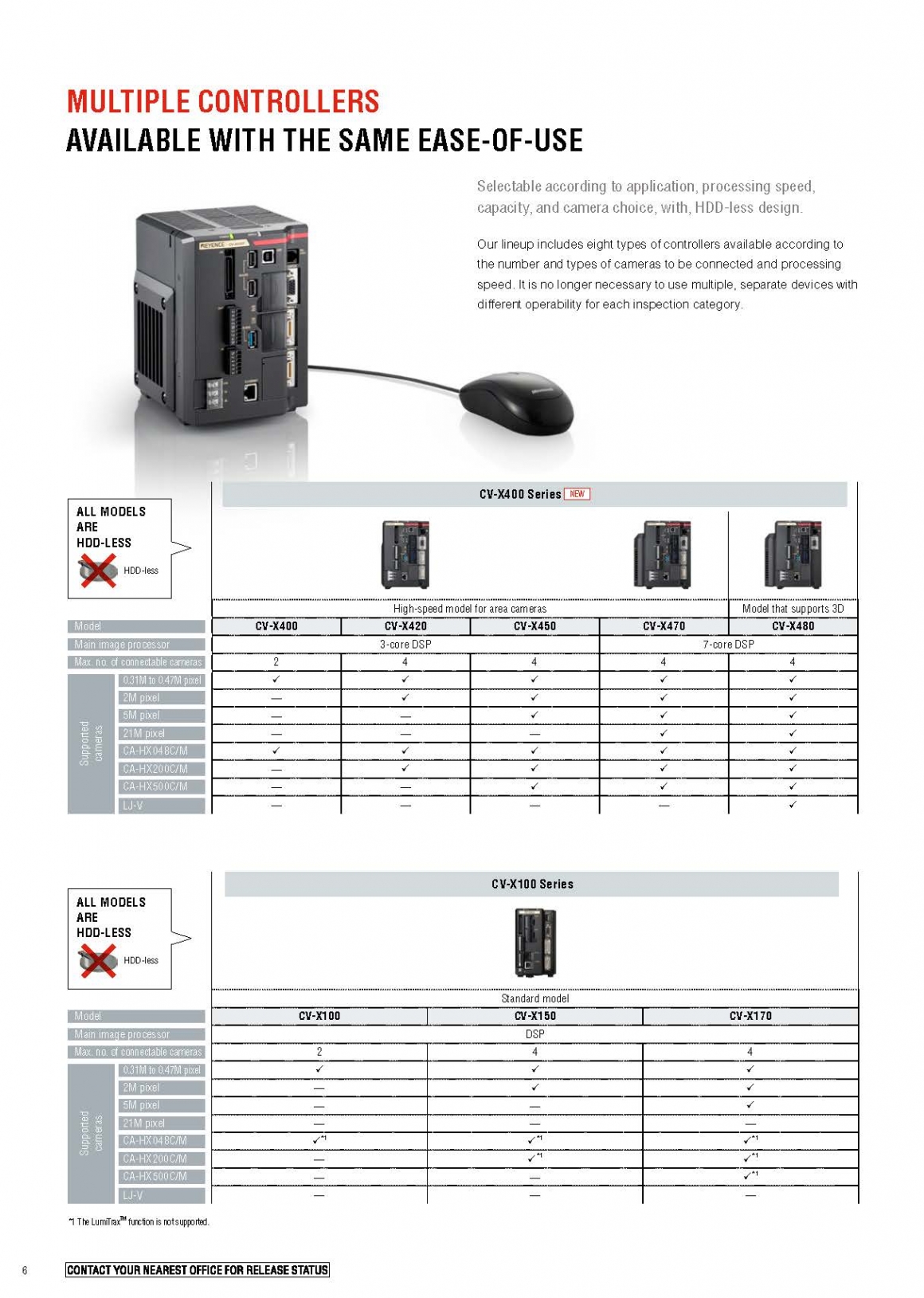

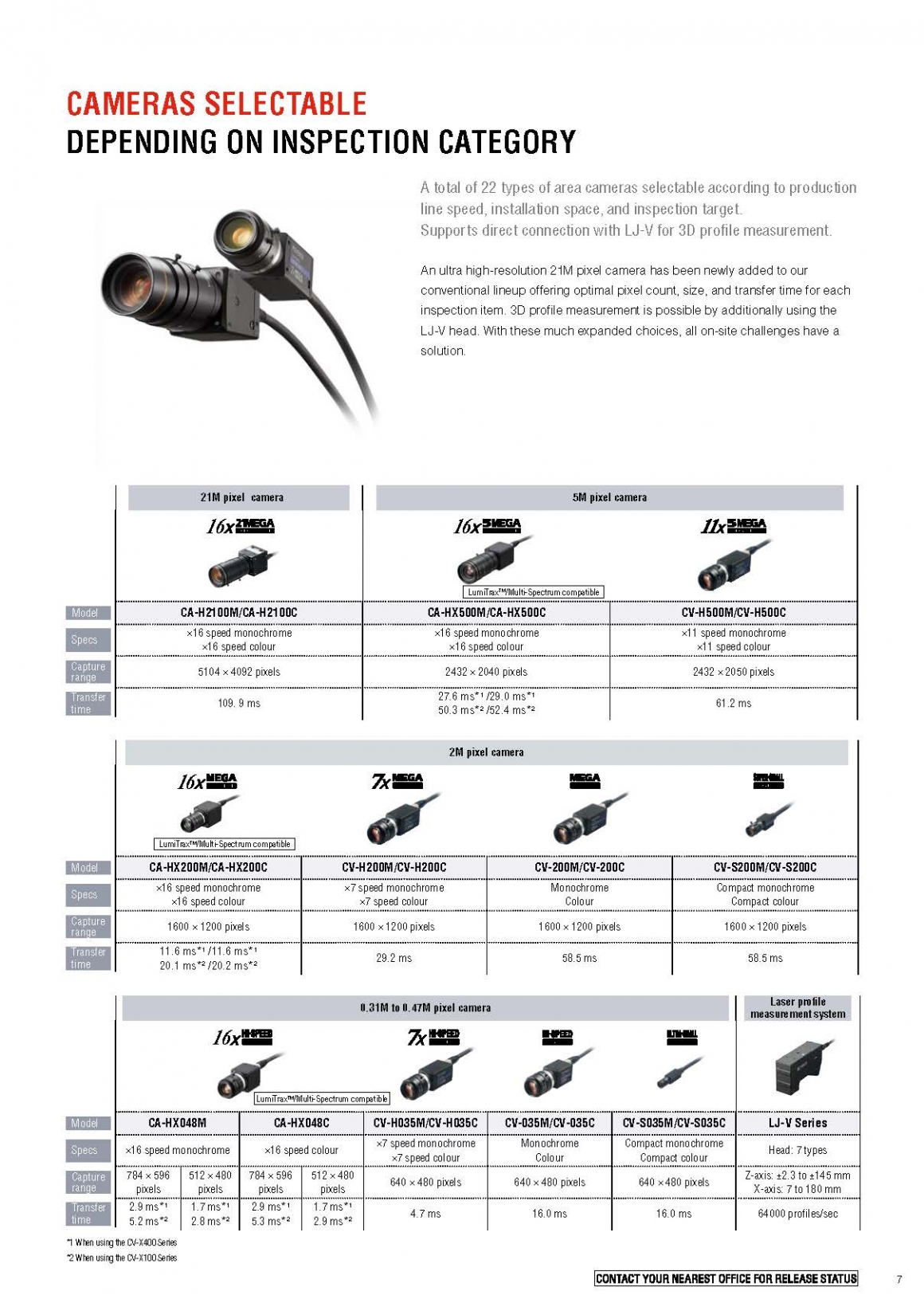

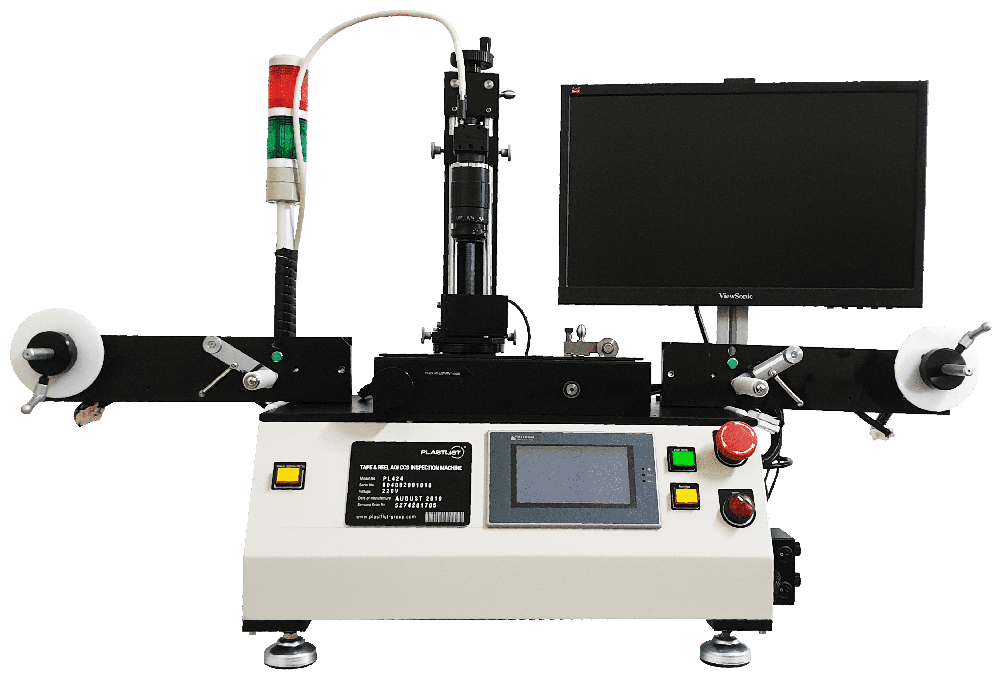

Tape and Reel AOI CCD Inspection System Keyence® Series

AOI CCD examination inspects:

- misplaced components

- reverse components

- missing components

- printing of part numbers and other codes

- component appearance comparison

- quantity counting

- auto-stop when component defection is found

- misplaced components

- reverse components

- missing components

- printing of part numbers and other codes

- component appearance comparison

- quantity counting

- auto-stop when component defection is found

Features

-Three stepper motor for synchronous feeding, positioning, and welding function.

-Rail width is from 8-56(mm) and can adjust by precision adjusting rod.

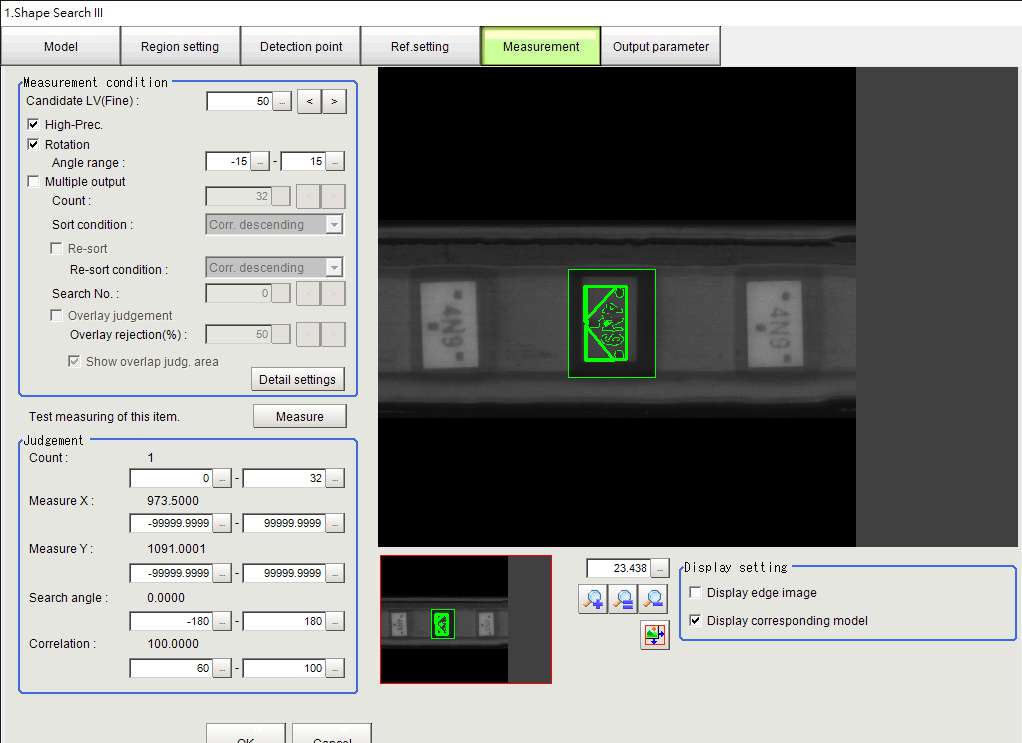

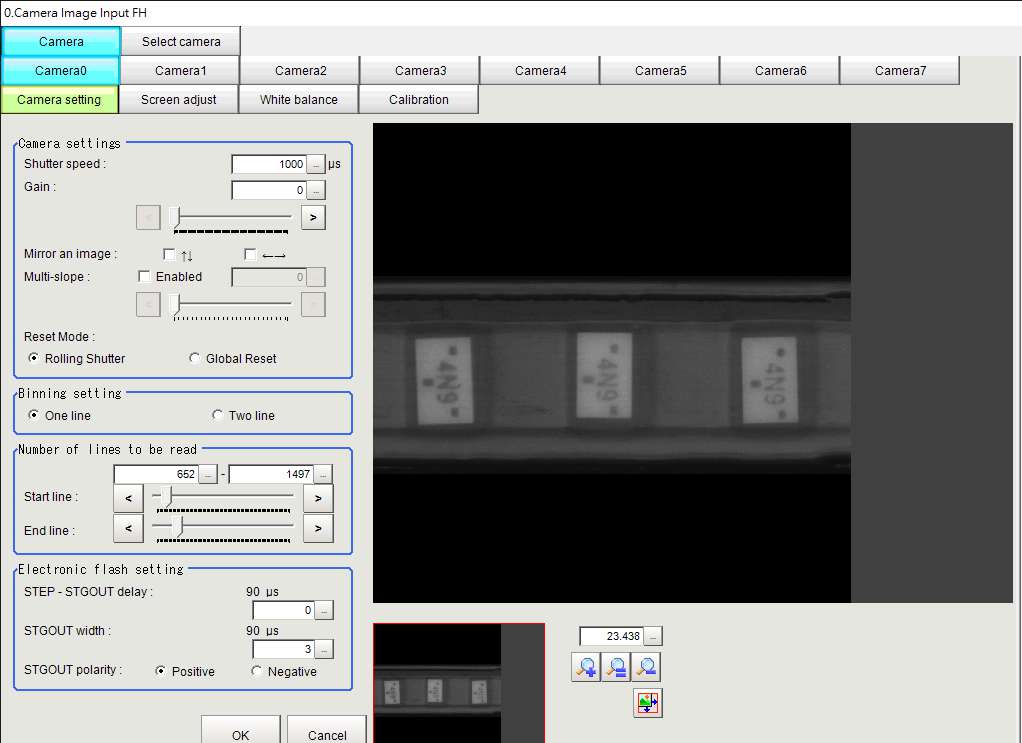

-Inspecting components with imported CCD lens (different components inspects with different CCD lens)

-The speed of examination is about 250-300pcs/min, and will different by pitch.

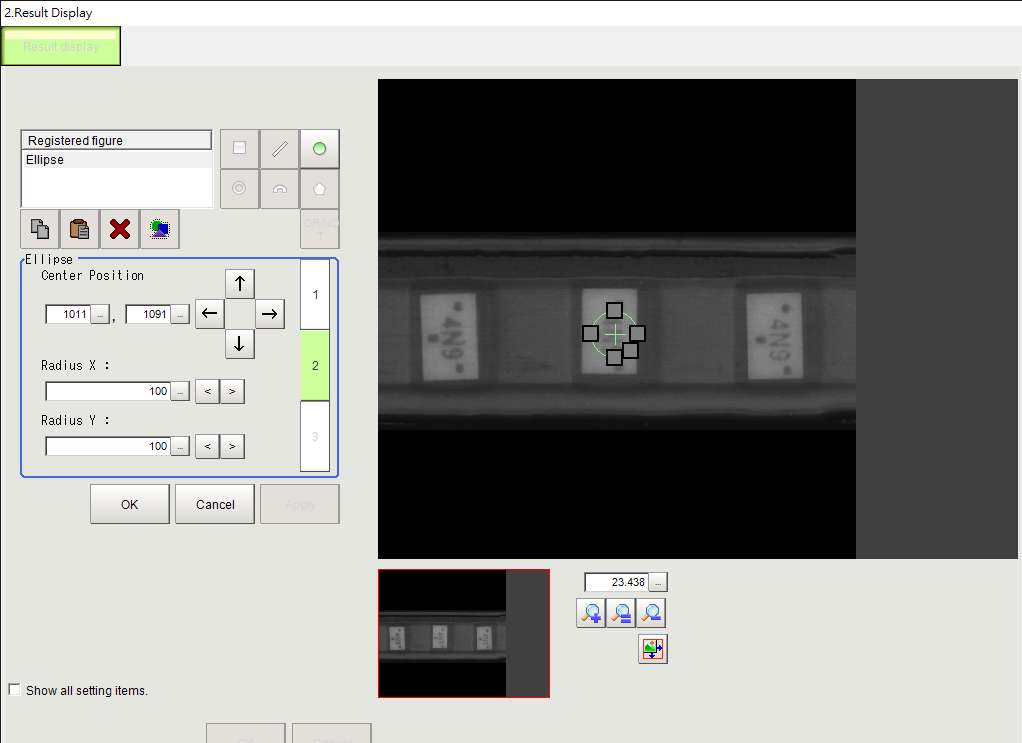

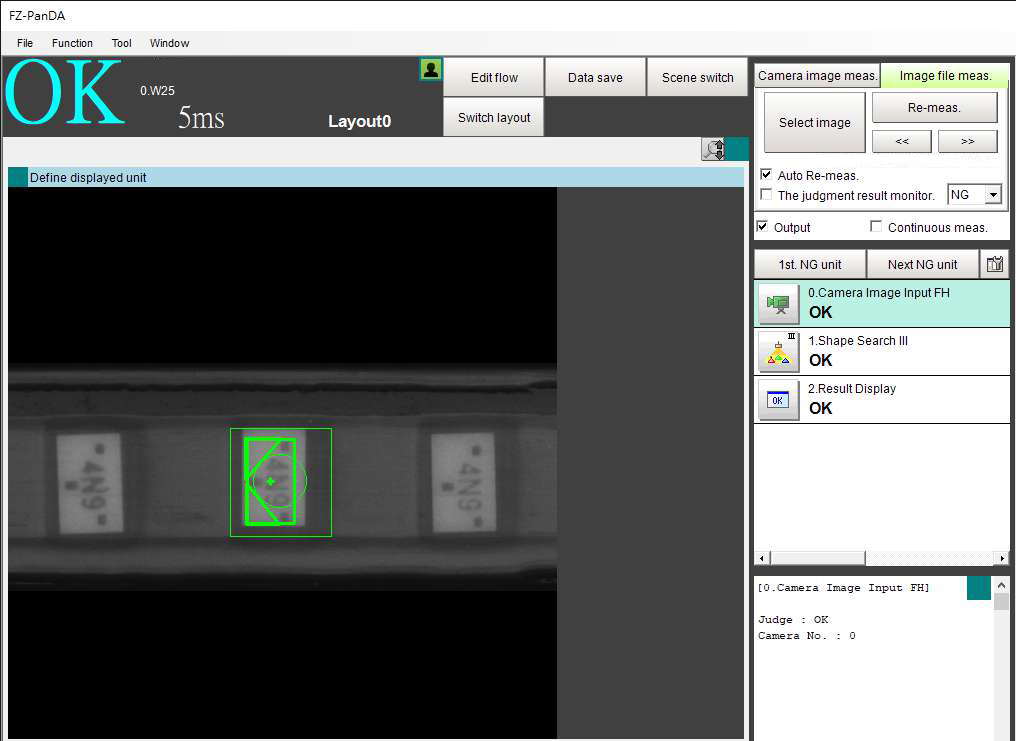

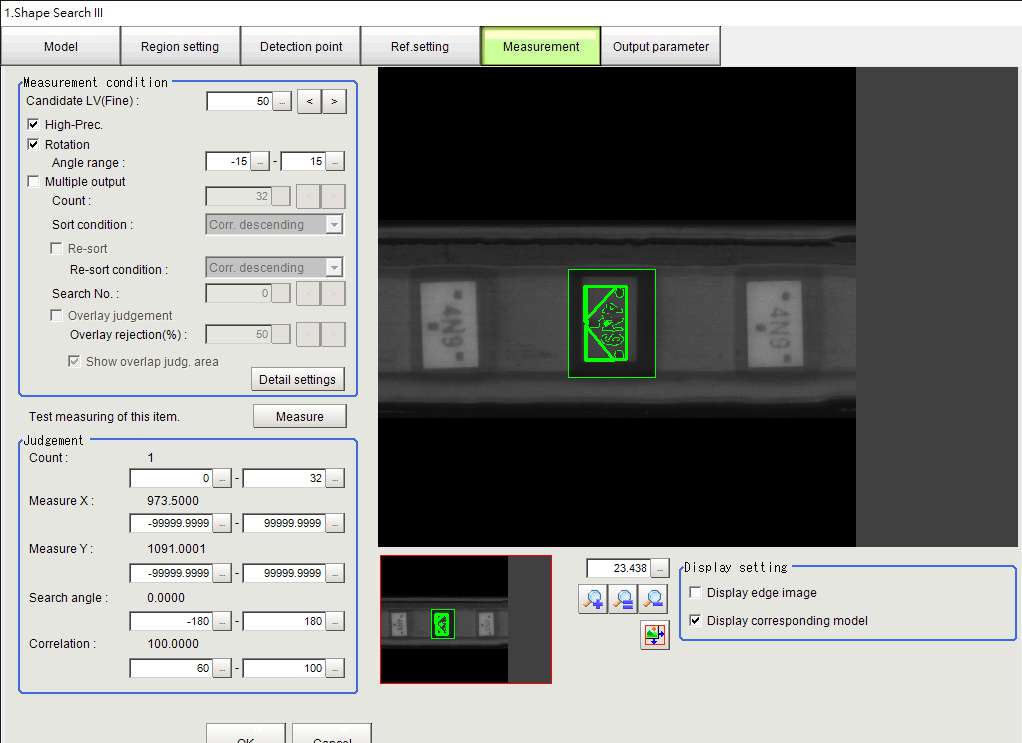

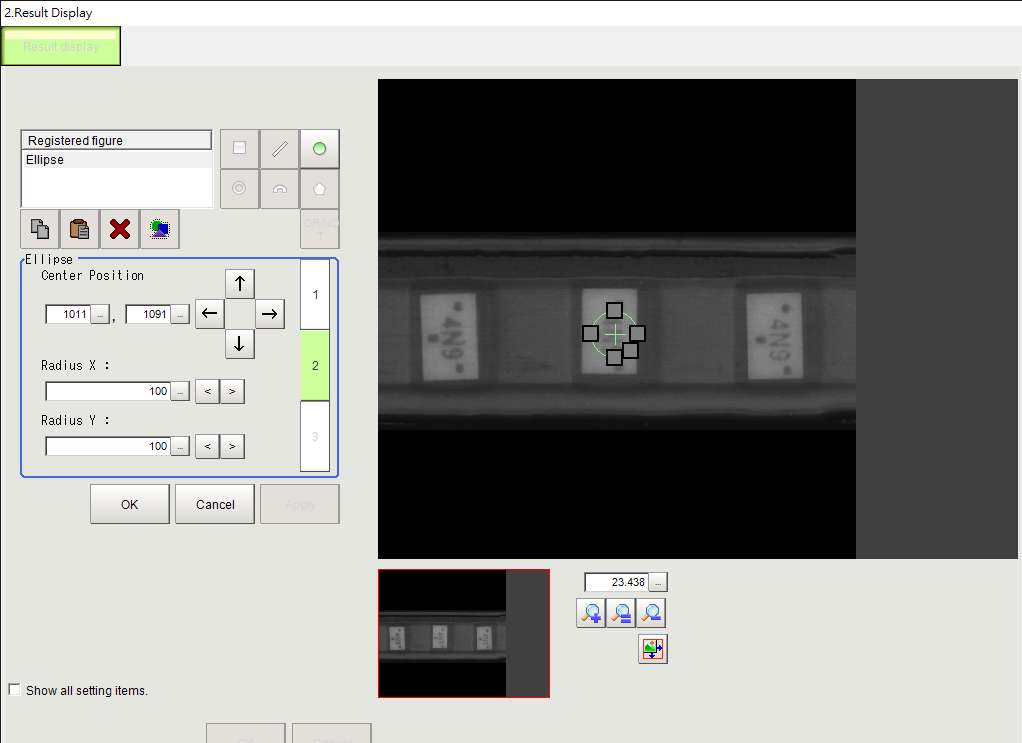

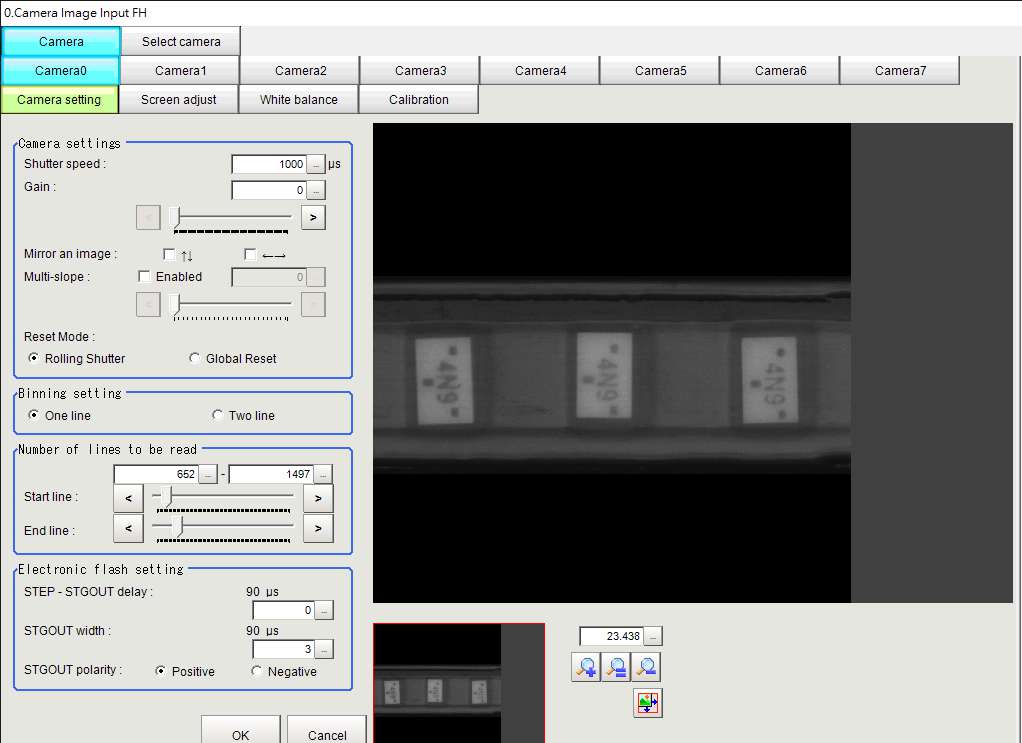

-The machine is installed in professional inspection software, friendly use and function well.

-AOI CCD examination inspects: appearance, lack of components, counting, and reversion. Please consider the actual inspection as final.

-MMI( man–machine interface) is used for set all parameters and speed function.

-Three stepper motor for synchronous feeding, positioning, and welding function.

-Rail width is from 8-56(mm) and can adjust by precision adjusting rod.

-Inspecting components with imported CCD lens (different components inspects with different CCD lens)

-The speed of examination is about 250-300pcs/min, and will different by pitch.

-The machine is installed in professional inspection software, friendly use and function well.

-AOI CCD examination inspects: appearance, lack of components, counting, and reversion. Please consider the actual inspection as final.

-MMI( man–machine interface) is used for set all parameters and speed function.

.jpg)

.jpg)

.jpg)